- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-12-20 Origin: Site

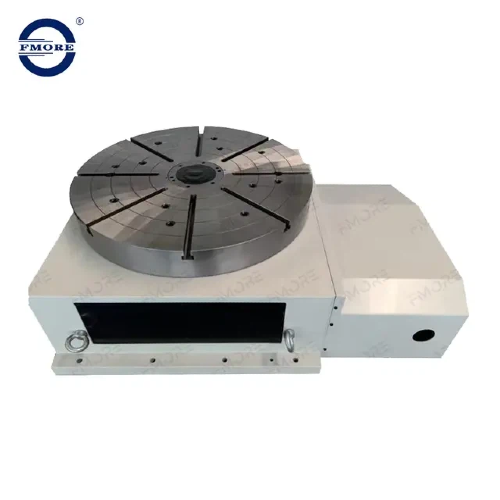

A Rotary Table is one of the most important auxiliary devices in modern machining, especially in CNC milling, drilling, and precision manufacturing. As manufacturing industries demand higher accuracy, better efficiency, and more complex part geometries, the rotary table has become an essential solution for achieving precise angular positioning and multi-sided machining in a single setup.

In simple terms, a rotary table allows a workpiece to rotate around a fixed axis at controlled angles or continuously. This capability significantly expands what a conventional milling machine or CNC machining center can accomplish. Instead of repositioning the workpiece manually, machinists can rely on the rotary table to perform accurate indexing, circular cutting, and complex contour machining.

The primary purpose of a Rotary Table is to provide controlled rotational movement of a workpiece during machining. This rotational capability allows for precise angular positioning, repetitive indexing, and continuous rotary cutting that cannot be achieved efficiently with linear motion alone.

One of the most important uses of a rotary table is accurate angular positioning.

During machining, many components require features such as equally spaced holes, slots, or contours arranged around a circular pattern. A rotary table allows the workpiece to rotate by a specific angle—manually or through CNC control—ensuring repeatable and precise positioning.

This precision is critical in industries such as automotive, aerospace, mold making, and mechanical engineering, where even minor angular deviations can cause assembly issues or functional failures.

Another key use of a rotary table is multi-sided machining in a single setup.

By rotating the workpiece to different angles, multiple faces can be machined without removing or repositioning the part. This approach reduces cumulative errors caused by repeated clamping and improves dimensional consistency across all sides of the workpiece.

Rotary tables are especially useful when machining complex geometries such as cams, impellers, turbine components, and precision mechanical parts.

A rotary table is widely used across different machining processes. Its versatility makes it suitable for both conventional milling machines and advanced CNC machining centers.

In milling operations, a rotary table enables a wide range of circular and angular machining tasks.

Rotary tables are commonly used for:

Circular milling of arcs and profiles

Machining round slots and curved surfaces

Creating complex contours with continuous rotation

By synchronizing the rotation of the table with the movement of the cutting tool, machinists can achieve smooth and accurate curved surfaces that would otherwise require complex programming or multiple setups.

Drilling and tapping operations benefit significantly from rotary table functionality, particularly in equally spaced hole patterns.

Typical applications include:

Bolt circle drilling

Flange hole machining

Index drilling on circular components

With a rotary table, holes can be drilled or tapped at precise angular intervals, ensuring uniform spacing and alignment. This is essential for components such as flanges, gears, and mechanical housings.

Rotary tables can operate in two main modes:

Indexing mode, where the table rotates to a fixed angle and stops

Continuous rotation mode, where the table rotates smoothly during cutting

Indexing is ideal for step-by-step machining tasks, while continuous rotation is used for circular contouring and advanced surface machining. This flexibility allows rotary tables to adapt to a wide variety of machining requirements.

With the growth of CNC technology, the rotary table has become a core component in modern machining centers.

In CNC machining, a rotary table often functions as the 4th axis, complementing the traditional X, Y, and Z linear axes.

Adding a rotary table as a fourth axis enables:

Machining of complex 3D shapes

Reduced setup time

Increased automation

Instead of repositioning the workpiece manually, CNC control allows precise rotational movements that are fully integrated into the machining program.

Using a rotary table in CNC machining improves both accuracy and efficiency.

By minimizing manual handling and reducing the number of setups, machining errors are significantly reduced. Additionally, cycle times are shortened because multiple operations can be performed in a single clamping.

This makes rotary tables an ideal solution for high-precision and high-volume production environments.

Different machining tasks require different types of rotary tables. Understanding these variations helps in selecting the most suitable solution.

A Horizontal Rotary Table has a horizontal rotating surface and is commonly used for heavy-duty machining.

Key characteristics:

High load capacity

Suitable for large and heavy workpieces

Often used in milling and drilling operations

Horizontal rotary tables are widely applied in general machining and industrial manufacturing due to their stability and versatility.

A Vertical Rotary Table features a vertical mounting orientation, making it easier to load and inspect parts.

Advantages include:

Better visibility of the workpiece

Convenient for precision machining

Ideal for smaller components

Vertical rotary tables are frequently used in tool rooms and precision machining applications.

This type of rotary table offers both horizontal and vertical mounting options.

Benefits include:

Flexible installation

Adaptability to different machining setups

Reduced need for multiple fixtures

Such rotary tables are particularly useful for workshops handling diverse machining tasks.

A Tilting Rotary Table adds angular tilting capability to the rotational motion.

This allows:

Machining at compound angles

Support for five-axis machining

Enhanced flexibility for complex parts

Tilting rotary tables are essential in aerospace, mold manufacturing, and high-end CNC applications.

A Pneumatic Rotary Table uses air pressure for rotation and indexing.

Key features:

Fast positioning

Suitable for automated production lines

Lower cost for light-duty applications

Pneumatic rotary tables are commonly used in assembly, inspection, and light machining processes.

The widespread adoption of rotary tables is driven by their significant advantages in machining operations.

Rotary tables provide precise angular control, which improves:

Positional accuracy

Repeatability

Consistency across multiple parts

This precision is especially important in high-tolerance machining environments.

By reducing setup changes and enabling multi-face machining, rotary tables:

Shorten production cycles

Reduce labor requirements

Improve overall equipment efficiency

These productivity gains directly translate into lower manufacturing costs.

Continuous rotary motion allows smoother cutting paths, resulting in:

Better surface finishes

Reduced tool marks

Improved overall part quality

This is particularly valuable in applications requiring high aesthetic or functional surface standards.

Selecting the correct rotary table requires careful consideration of multiple factors.

The rotary table must support the weight and size of the workpiece without compromising accuracy or stability.

Different applications demand different levels of precision. High-accuracy rotary tables are essential for aerospace and precision engineering applications.

Ensure the rotary table is compatible with your CNC control system and supports the required communication and control protocols.

Consider whether your application requires:

Continuous rotation

Indexing only

Tilting or multi-axis capability

Matching the rotary table features to your specific needs ensures optimal performance.

Rotary Table Type | Main Features | Typical Applications |

Horizontal Rotary Table | High load capacity, stable | Heavy-duty milling, drilling |

Vertical Rotary Table | Easy access, precision | Tool rooms, fine machining |

Horizontal & Vertical | Flexible mounting | Multi-purpose machining |

Tilting Rotary Table | Multi-angle machining | Aerospace, mold making |

Pneumatic Rotary Table | Fast indexing | Automation, light-duty tasks |

A Rotary Table is far more than a simple accessory—it is a key component that enables higher machining precision, greater flexibility, and improved productivity. By allowing accurate rotational positioning and multi-face machining in a single setup, rotary tables help manufacturers handle complex geometries, reduce setup time, and achieve consistent, high-quality results. Whether applied in conventional milling or integrated into advanced CNC machining centers, rotary tables play a vital role in modern precision manufacturing.

As the manufacturing industry continues to move toward higher accuracy, automation, and efficiency, the demand for reliable and well-engineered rotary tables will only continue to grow. Selecting the right rotary table is not just a technical decision—it is an investment in long-term performance, cost control, and production stability.

At YANTAI FORMORE MACHINERY CO., LTD., we specialize in providing high-quality rotary tables designed to meet diverse machining requirements. With extensive industry experience, strict quality control, and a wide range of rotary table solutions, we are committed to helping customers improve machining capability and operational efficiency. If you are looking for a dependable rotary table solution or need professional support in selecting the right model, we welcome you to contact us and learn more about how we can support your machining needs.

The main purpose of a rotary table is to rotate a workpiece accurately during machining, enabling precise angular positioning and complex machining operations.

No, rotary tables can be used on both conventional milling machines and CNC machining centers, although CNC applications offer greater automation and precision.

A rotary table supports both continuous rotation and precise indexing, while an indexer is mainly designed for fixed-step angular positioning.

Yes, by reducing manual repositioning and ensuring consistent angular movement, rotary tables significantly improve machining accuracy and repeatability.

You should consider load capacity, accuracy requirements, machine compatibility, and the specific machining tasks you need to perform.