- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

The design of the lathe chuck is tailored to meet the diverse needs of these applications. The body is made from durable materials to withstand the forces involved in machining different materials. The jaws are designed to provide a secure grip, with options for self-centering or independent adjustment. The clamping mechanism is engineered for ease of use and reliability, whether it's a key-operated or power-driven system.

One of the main advantages in these applications is the ability to hold workpieces securely. This ensures that the machining operations can be carried out accurately, reducing the risk of errors and improving the quality of the final product. The versatility of the lathe chuck, with its different jaw options, allows it to adapt to various workpiece shapes and sizes, increasing its utility in different manufacturing processes.

Short cylindrical center mounting.

K11 chucks are provided with one-piece jaw ,including a set of internal jaws and a set of external jaws.

Jaws for K11A,K11C,K11D chucks are composed of two-piece jaws.They can perform as either internal or external jaws through adjustment.

Jaws for K11A,K11D chucks conform to ISO3442 standard.

K11C chucks are suppled with traditional two-piece jaws.

Body materials are classified as wear-resisting alloy cast iron.

The design of the lathe chuck is tailored to meet the diverse needs of these applications. The body is made from durable materials to withstand the forces involved in machining different materials. The jaws are designed to provide a secure grip, with options for self-centering or independent adjustment. The clamping mechanism is engineered for ease of use and reliability, whether it's a key-operated or power-driven system.

One of the main advantages in these applications is the ability to hold workpieces securely. This ensures that the machining operations can be carried out accurately, reducing the risk of errors and improving the quality of the final product. The versatility of the lathe chuck, with its different jaw options, allows it to adapt to various workpiece shapes and sizes, increasing its utility in different manufacturing processes.

Short cylindrical center mounting.

K11 chucks are provided with one-piece jaw ,including a set of internal jaws and a set of external jaws.

Jaws for K11A,K11C,K11D chucks are composed of two-piece jaws.They can perform as either internal or external jaws through adjustment.

Jaws for K11A,K11D chucks conform to ISO3442 standard.

K11C chucks are suppled with traditional two-piece jaws.

Body materials are classified as wear-resisting alloy cast iron.

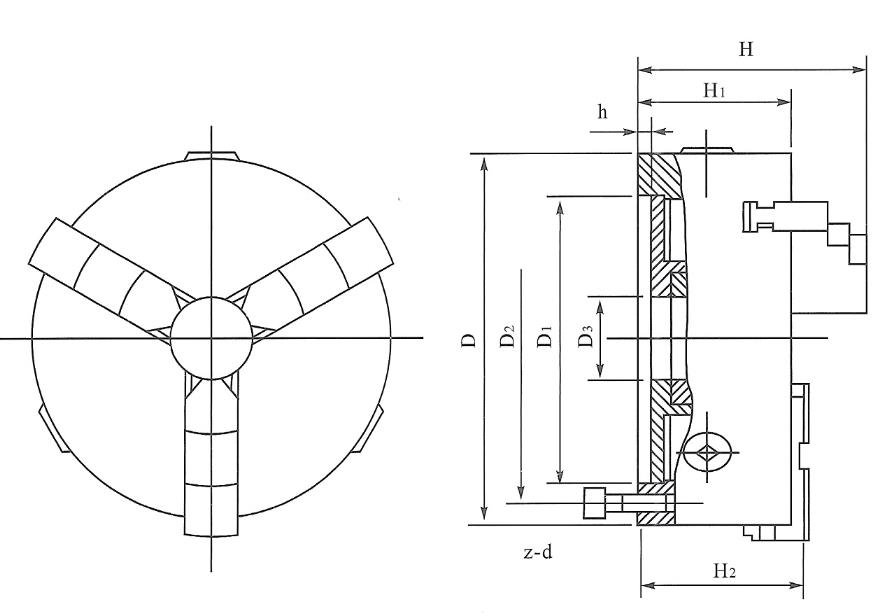

| Model D | D1 | D2 | D3 | H | H1 | H2 | h | z-d | N.W.kg |

| 80 | 55 | 66 | 16 | 66 | 50 | - | 3.5 | 3-M6 | 1.9 |

| 100 | 72 | 84 | 22 | 74.5 | 55 | - | 3.5 | 3-M6 | 3.2 |

| 125 | 95 | 108 | 30 | 78 | 55 | - | 4 | 3-M8 | 5 |

| 130 | 100 | 115 | 30 | 78 | 55 | - | 3.5 | 3-M8 | 5.6 |

| 160 | 130 | 142 | 40 | 93 | 65 | - | 5 | 3-M8 | 8.8 |

| 160A | 130 | 142 | 40 | 109 | 65 | 71 | 5 | 3-M8 | 8.3 |

| 165 | 130 | 145 | 40 | 93 | 65 | - | 5 | 3-M8 | 9.5 |

| 190 | 155 | 172 | 55 | 105 | 75 | - | 5 | 3-M10 | 13.8 |

| 200 | 165 | 180 | 65 | 109 | 75 | - | 5 | 3-M10 | 15.5 |

| 200C | 165 | 180 | 65 | 122 | 75 | 78 | 5 | 3-M10 | 14.1 |

| 200A | 165 | 180 | 65 | 122 | 75 | 80 | 5 | 3-M10 | 14.1 |

| 240 | 195 | 215 | 70 | 120 | 80 | - | 8 | 3-M12 | 24 |

| 240A | 195 | 215 | 70 | 134 | 80 | 85 | 8 | 3-M12 | 20 |

| 250 | 206 | 226 | 80 | 120 | 80 | - | 5 | 3-M12 | 25.7 |

| 250C | 206 | 226 | 80 | 130 | 80 | 84 | 5 | 3-M12 | 23 |

| 250A | 206 | 226 | 80 | 134 | 80 | 86 | 5 | 3-M12 | 23 |

| 315 | 280 | 285 | 100 | 141 | 90 | - | 6 | 3-M16 | 47 |

| 315C | 260 | 285 | 100 | 147 | 90 | 95 | 6 | 3-M16 | 41 |

| 315A | 260 | 285 | 100 | 154 | 90 | 96 | 6 | 3-M16 | 41 |

| 320 | 270 | 290 | 100 | 154 | 95 | - | 6 | 3-M16 | 47.5 |

| 320C | 270 | 290 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 42 |

| 320A | 270 | 290 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 42 |

| 325 | 272 | 296 | 100 | 154 | 90 | - | 6 | 3-M16 | 49 |

| 325C | 272 | 296 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 44 |

| 325A | 272 | 296 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 46 |

| 380 | 325 | 350 | 130 | 155.5 | 100 | - | 6 | 3-M16 | 65 |

| 380C | 325 | 350 | 130 | 155.5 | 100 | 96.5 | 6 | 3-M16 | 60 |

| 380A | 325 | 350 | 130 | 170.5 | 100 | 96.5 | 6 | 3-M16 | 62 |

| 400 | 340 | 368 | 130 | 155.5 | 100 | - | 6 | 3-M16 | 74 |

| 400A | 340 | 368 | 130 | 170.5 | 100 | 108.5 | 6 | 3-M16 | 71 |

| 500 | 440 | 465 | 200 | 176 | 115 | - | 6 | 3-M16 | 124 |

| 500A | 440 | 465 | 200 | 203 | 115 | 123 | 6 | 3-M16 | 119 |

| 500D | 440 | 465 | 200 | 203 | 115 | 123 | 6 | 3-M16 | 117 |

| 630 | 560 | 595 | 260 | 130 | - | 7 | 3-M16 | 217 | |

| 630A | 560 | 595 | 260 | 218 | 130 | 138 | 7 | 3-M16 | 208 |

| 800A | 710 | 760 | 385 | 249 | 148 | 158 | 8 | 3-M20 | 250 |

| 1000A | 910 | 950 | 460 | 266 | 165 | 216 | 8 | 3-M24 | 746 |

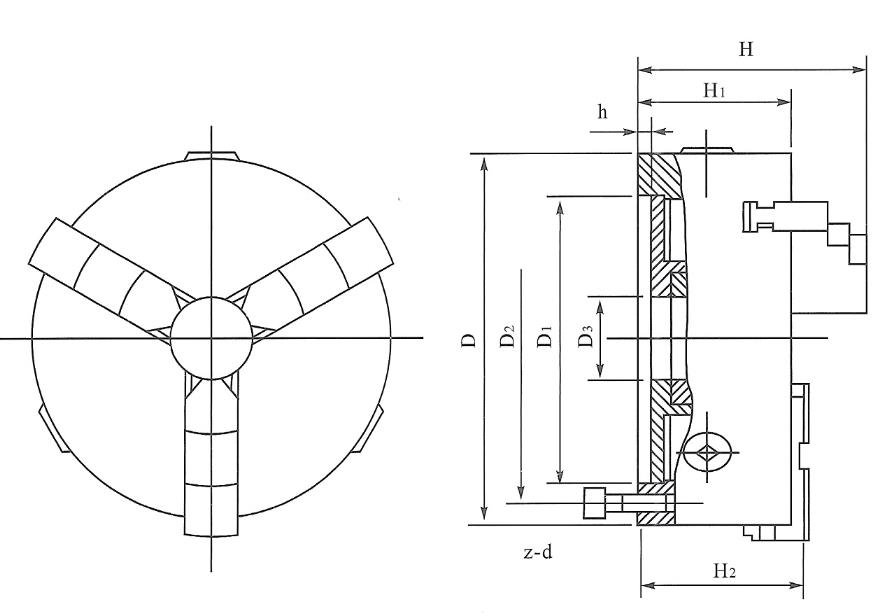

| Model D | D1 | D2 | D3 | H | H1 | H2 | h | z-d | N.W.kg |

| 80 | 55 | 66 | 16 | 66 | 50 | - | 3.5 | 3-M6 | 1.9 |

| 100 | 72 | 84 | 22 | 74.5 | 55 | - | 3.5 | 3-M6 | 3.2 |

| 125 | 95 | 108 | 30 | 78 | 55 | - | 4 | 3-M8 | 5 |

| 130 | 100 | 115 | 30 | 78 | 55 | - | 3.5 | 3-M8 | 5.6 |

| 160 | 130 | 142 | 40 | 93 | 65 | - | 5 | 3-M8 | 8.8 |

| 160A | 130 | 142 | 40 | 109 | 65 | 71 | 5 | 3-M8 | 8.3 |

| 165 | 130 | 145 | 40 | 93 | 65 | - | 5 | 3-M8 | 9.5 |

| 190 | 155 | 172 | 55 | 105 | 75 | - | 5 | 3-M10 | 13.8 |

| 200 | 165 | 180 | 65 | 109 | 75 | - | 5 | 3-M10 | 15.5 |

| 200C | 165 | 180 | 65 | 122 | 75 | 78 | 5 | 3-M10 | 14.1 |

| 200A | 165 | 180 | 65 | 122 | 75 | 80 | 5 | 3-M10 | 14.1 |

| 240 | 195 | 215 | 70 | 120 | 80 | - | 8 | 3-M12 | 24 |

| 240A | 195 | 215 | 70 | 134 | 80 | 85 | 8 | 3-M12 | 20 |

| 250 | 206 | 226 | 80 | 120 | 80 | - | 5 | 3-M12 | 25.7 |

| 250C | 206 | 226 | 80 | 130 | 80 | 84 | 5 | 3-M12 | 23 |

| 250A | 206 | 226 | 80 | 134 | 80 | 86 | 5 | 3-M12 | 23 |

| 315 | 280 | 285 | 100 | 141 | 90 | - | 6 | 3-M16 | 47 |

| 315C | 260 | 285 | 100 | 147 | 90 | 95 | 6 | 3-M16 | 41 |

| 315A | 260 | 285 | 100 | 154 | 90 | 96 | 6 | 3-M16 | 41 |

| 320 | 270 | 290 | 100 | 154 | 95 | - | 6 | 3-M16 | 47.5 |

| 320C | 270 | 290 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 42 |

| 320A | 270 | 290 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 42 |

| 325 | 272 | 296 | 100 | 154 | 90 | - | 6 | 3-M16 | 49 |

| 325C | 272 | 296 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 44 |

| 325A | 272 | 296 | 100 | 154 | 90 | 96.5 | 6 | 3-M16 | 46 |

| 380 | 325 | 350 | 130 | 155.5 | 100 | - | 6 | 3-M16 | 65 |

| 380C | 325 | 350 | 130 | 155.5 | 100 | 96.5 | 6 | 3-M16 | 60 |

| 380A | 325 | 350 | 130 | 170.5 | 100 | 96.5 | 6 | 3-M16 | 62 |

| 400 | 340 | 368 | 130 | 155.5 | 100 | - | 6 | 3-M16 | 74 |

| 400A | 340 | 368 | 130 | 170.5 | 100 | 108.5 | 6 | 3-M16 | 71 |

| 500 | 440 | 465 | 200 | 176 | 115 | - | 6 | 3-M16 | 124 |

| 500A | 440 | 465 | 200 | 203 | 115 | 123 | 6 | 3-M16 | 119 |

| 500D | 440 | 465 | 200 | 203 | 115 | 123 | 6 | 3-M16 | 117 |

| 630 | 560 | 595 | 260 | 130 | - | 7 | 3-M16 | 217 | |

| 630A | 560 | 595 | 260 | 218 | 130 | 138 | 7 | 3-M16 | 208 |

| 800A | 710 | 760 | 385 | 249 | 148 | 158 | 8 | 3-M20 | 250 |

| 1000A | 910 | 950 | 460 | 266 | 165 | 216 | 8 | 3-M24 | 746 |

Q: Can a lathe chuck be used for very small workpieces?

A: Yes, there are lathe chucks specifically designed for holding small workpieces. These chucks often have smaller jaw openings and more precise clamping mechanisms to accommodate the delicate nature of small parts. However, for extremely small workpieces, additional fixtures or collets may be required in combination with the chuck to ensure a secure hold.

Q: How do I select the appropriate clamping force for my workpiece?

A: The clamping force depends on the material, size, and shape of the workpiece. For soft materials, a lower clamping force is usually sufficient to avoid damaging the workpiece. For hard materials or large workpieces, a higher clamping force may be needed to prevent the workpiece from moving during machining. It's also important to consider the machining operation being performed, as some operations may generate more forces and require a stronger clamping force.

Q: Are there any safety precautions I should take when using a lathe chuck?

A: Yes, when using a lathe chuck, always ensure that the chuck is properly mounted on the lathe spindle and that the jaws are tightened securely before starting the machining operation. Keep your hands and other objects away from the rotating chuck and workpiece. Use appropriate personal protective equipment, such as safety glasses and gloves. Also, make sure to disconnect the power source when changing the workpiece or performing maintenance on the chuck.

Q: Can a lathe chuck be used for very small workpieces?

A: Yes, there are lathe chucks specifically designed for holding small workpieces. These chucks often have smaller jaw openings and more precise clamping mechanisms to accommodate the delicate nature of small parts. However, for extremely small workpieces, additional fixtures or collets may be required in combination with the chuck to ensure a secure hold.

Q: How do I select the appropriate clamping force for my workpiece?

A: The clamping force depends on the material, size, and shape of the workpiece. For soft materials, a lower clamping force is usually sufficient to avoid damaging the workpiece. For hard materials or large workpieces, a higher clamping force may be needed to prevent the workpiece from moving during machining. It's also important to consider the machining operation being performed, as some operations may generate more forces and require a stronger clamping force.

Q: Are there any safety precautions I should take when using a lathe chuck?

A: Yes, when using a lathe chuck, always ensure that the chuck is properly mounted on the lathe spindle and that the jaws are tightened securely before starting the machining operation. Keep your hands and other objects away from the rotating chuck and workpiece. Use appropriate personal protective equipment, such as safety glasses and gloves. Also, make sure to disconnect the power source when changing the workpiece or performing maintenance on the chuck.

content is empty!