- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

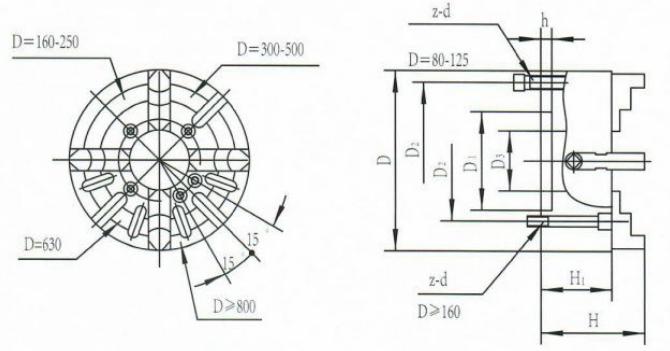

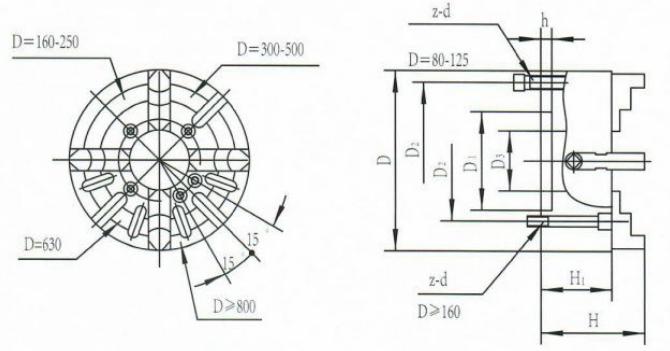

The design of the lathe chuck is a complex combination of mechanical engineering principles. The body is designed for strength and stability, with a focus on minimizing vibrations. The jaws are crafted from high-quality materials to provide a secure grip. The clamping mechanism, whether key-operated or power-driven, is designed for ease of use and reliability.

The lathe chuck offers several advantages, including its ability to hold workpieces securely, its versatility in handling different workpiece shapes and sizes, and its contribution to achieving high precision in machining operations. It also enhances the efficiency of the machining process by reducing setup time and allowing for quick tool changes in some cases.

Short cylindrical center mounting.

K72 chucks are provided with one-piece jaw which can perform as either internal or external jaws through adjustment.

K72/A2, K72/C, K72/D chucks can be directly mounted to the spindle of machine tools.

Jaws are Independent and adjustable, suitable for machining all kinds of special shaped parts.

Body materials are classified as wear-resisting alloy cast iron.

The design of the lathe chuck is a complex combination of mechanical engineering principles. The body is designed for strength and stability, with a focus on minimizing vibrations. The jaws are crafted from high-quality materials to provide a secure grip. The clamping mechanism, whether key-operated or power-driven, is designed for ease of use and reliability.

The lathe chuck offers several advantages, including its ability to hold workpieces securely, its versatility in handling different workpiece shapes and sizes, and its contribution to achieving high precision in machining operations. It also enhances the efficiency of the machining process by reducing setup time and allowing for quick tool changes in some cases.

Short cylindrical center mounting.

K72 chucks are provided with one-piece jaw which can perform as either internal or external jaws through adjustment.

K72/A2, K72/C, K72/D chucks can be directly mounted to the spindle of machine tools.

Jaws are Independent and adjustable, suitable for machining all kinds of special shaped parts.

Body materials are classified as wear-resisting alloy cast iron.

| Model D | D1 | D2 | D3 | H | H1 | h | z-d | N.W.kg |

| 80 | 55 | 66 | 22 | 59 | 43 | 3.5 | 4-M6 | 2 |

| 100 | 72 | 84 | 25 | 77 | 54 | 3.5 | 4-M8 | 3 |

| 125 | 95 | 108 | 30 | 78 | 56 | 4.5 | 4-M8 | 5 |

| 160 | 65 | 95 | 45 | 93 | 65 | 5 | 4-M10 | 9 |

| 200 | 75 | 112 | 55 | 107 | 75 | 6 | 4-M10 | 15 |

| 250 | 110 | 130 | 75 | 120 | 80 | 6 | 4-M12 | 23 |

| 300 | 152 | 130 | 75 | 134 | 90 | 6 | 4-M12 | 39 |

| 320 | 140 | 165 | 95 | 134 | 90 | 6 | 4-M16 | 40 |

| 350 | 130 | 168 | 95 | 134 | 90 | 6 | 4-M16 | 53 |

| 400 | 160 | 185 | 125 | 143 | 95 | 8 | 4-M16 | 55 |

| 450 | 180 | 205 | 140 | 147 | 100 | 8 | 4-M16 | 71 |

| 500 | 200 | 236 | 160 | 160 | 105 | 8 | 4-M20 | 102 |

| 520 | 260 | 300 | 205 | 160 | 105 | 10 | 4-M16 | 112 |

| 630 | 220 | 258 | 180 | 180 | 116 | 10 | 4-M20 | 159 |

| 800 | 250 | 300 | 210 | 210 | 135 | 12 | 8-M20 | 255 |

| 1000 | 320 | 370 | 260 | 230 | 150 | 15 | 8-M20 | 418 |

| 1250 | 400 | 500 | 305 | 256 | 165 | 15 | 8-M20 | - |

| 1400 | 400 | 500 | 305 | 246 | 155 | 15 | 8-M20 | - |

| 1600 | 420 | 520 | 320 | 266 | 175 | 20 | 8-M24 | - |

| 2000 | 450 | 560 | 350 | 290 | 190 | 20 | 8-M30 | - |

| Model D | D1 | D2 | D3 | H | H1 | h | z-d | N.W.kg |

| 80 | 55 | 66 | 22 | 59 | 43 | 3.5 | 4-M6 | 2 |

| 100 | 72 | 84 | 25 | 77 | 54 | 3.5 | 4-M8 | 3 |

| 125 | 95 | 108 | 30 | 78 | 56 | 4.5 | 4-M8 | 5 |

| 160 | 65 | 95 | 45 | 93 | 65 | 5 | 4-M10 | 9 |

| 200 | 75 | 112 | 55 | 107 | 75 | 6 | 4-M10 | 15 |

| 250 | 110 | 130 | 75 | 120 | 80 | 6 | 4-M12 | 23 |

| 300 | 152 | 130 | 75 | 134 | 90 | 6 | 4-M12 | 39 |

| 320 | 140 | 165 | 95 | 134 | 90 | 6 | 4-M16 | 40 |

| 350 | 130 | 168 | 95 | 134 | 90 | 6 | 4-M16 | 53 |

| 400 | 160 | 185 | 125 | 143 | 95 | 8 | 4-M16 | 55 |

| 450 | 180 | 205 | 140 | 147 | 100 | 8 | 4-M16 | 71 |

| 500 | 200 | 236 | 160 | 160 | 105 | 8 | 4-M20 | 102 |

| 520 | 260 | 300 | 205 | 160 | 105 | 10 | 4-M16 | 112 |

| 630 | 220 | 258 | 180 | 180 | 116 | 10 | 4-M20 | 159 |

| 800 | 250 | 300 | 210 | 210 | 135 | 12 | 8-M20 | 255 |

| 1000 | 320 | 370 | 260 | 230 | 150 | 15 | 8-M20 | 418 |

| 1250 | 400 | 500 | 305 | 256 | 165 | 15 | 8-M20 | - |

| 1400 | 400 | 500 | 305 | 246 | 155 | 15 | 8-M20 | - |

| 1600 | 420 | 520 | 320 | 266 | 175 | 20 | 8-M24 | - |

| 2000 | 450 | 560 | 350 | 290 | 190 | 20 | 8-M30 | - |

Q: How do I install a lathe chuck on my lathe spindle?

A: First, ensure that the lathe spindle and the chuck mounting interface are clean and free of any debris. For chucks with a Morse taper mounting, apply a thin layer of lubricant to the taper. Align the chuck with the spindle and gently tap it into place using a soft mallet. For threaded chucks, carefully thread the chuck onto the spindle, making sure to tighten it evenly to avoid any misalignment. After installation, check the chuck's runout using a dial indicator to ensure it is rotating concentrically with the spindle.

Q: What should I do if the jaws of my lathe chuck are not closing evenly?

A: If the jaws of your lathe chuck are not closing evenly, first check if there is any debris or chips stuck between the jaws or in the scroll mechanism (for self-centering chucks). Clean the area thoroughly using a brush and compressed air. If the problem persists, inspect the jaws for any signs of wear or damage. Worn jaws may need to be replaced. For independent chucks, check if the individual screw mechanisms are functioning properly and adjust them if necessary. It's also possible that the chuck has been misaligned during installation, in which case you may need to reinstall it.

Q: Can I use a lathe chuck for high-speed machining?

A: Yes, many lathe chucks are designed to be used for high-speed machining. However, it's important to ensure that the chuck is balanced properly and that the clamping force is sufficient to hold the workpiece securely at high speeds. For high-speed applications, it's recommended to use chucks with a higher speed rating and to follow the manufacturer's guidelines regarding maximum speeds and clamping forces. Additionally, regular maintenance and inspection of the chuck are crucial to prevent any issues that may arise due to the increased stresses at high speeds.

Q: How do I install a lathe chuck on my lathe spindle?

A: First, ensure that the lathe spindle and the chuck mounting interface are clean and free of any debris. For chucks with a Morse taper mounting, apply a thin layer of lubricant to the taper. Align the chuck with the spindle and gently tap it into place using a soft mallet. For threaded chucks, carefully thread the chuck onto the spindle, making sure to tighten it evenly to avoid any misalignment. After installation, check the chuck's runout using a dial indicator to ensure it is rotating concentrically with the spindle.

Q: What should I do if the jaws of my lathe chuck are not closing evenly?

A: If the jaws of your lathe chuck are not closing evenly, first check if there is any debris or chips stuck between the jaws or in the scroll mechanism (for self-centering chucks). Clean the area thoroughly using a brush and compressed air. If the problem persists, inspect the jaws for any signs of wear or damage. Worn jaws may need to be replaced. For independent chucks, check if the individual screw mechanisms are functioning properly and adjust them if necessary. It's also possible that the chuck has been misaligned during installation, in which case you may need to reinstall it.

Q: Can I use a lathe chuck for high-speed machining?

A: Yes, many lathe chucks are designed to be used for high-speed machining. However, it's important to ensure that the chuck is balanced properly and that the clamping force is sufficient to hold the workpiece securely at high speeds. For high-speed applications, it's recommended to use chucks with a higher speed rating and to follow the manufacturer's guidelines regarding maximum speeds and clamping forces. Additionally, regular maintenance and inspection of the chuck are crucial to prevent any issues that may arise due to the increased stresses at high speeds.

content is empty!