- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

| Availability: | |

|---|---|

| Quantity: | |

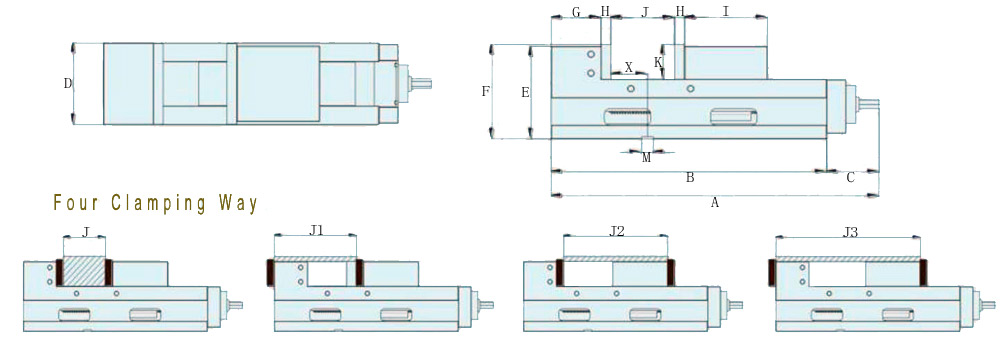

1. Suitable for heavy cutting in vertical and horizontal cutting machine FMS systems.

2. Precise hydraulic clamping force doubling design, easy to operate, suitable for light and heavy cutting

3. The body and the fixed jaw are integrally formed, and the workpiece wont go upwards when clamped.

4. The sliding surface of vise has been hardened to HRC45 or higher, ensuring long-term wear resistance.

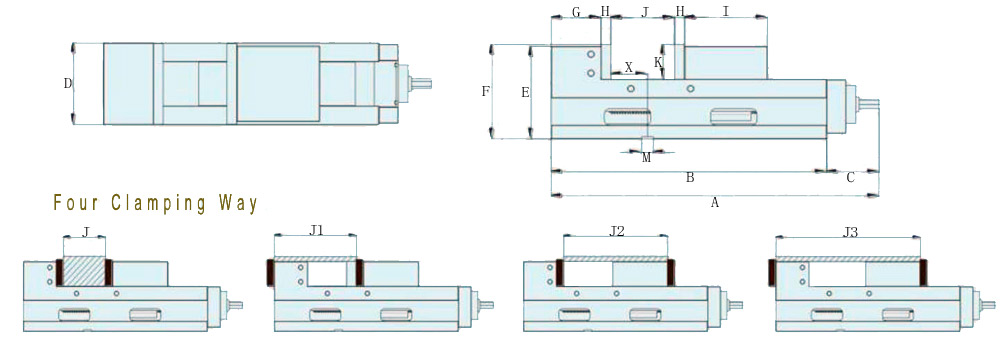

5. Four clamping ways meet with different requirments.

6. Material: Ductile cast iron.

1. Suitable for heavy cutting in vertical and horizontal cutting machine FMS systems.

2. Precise hydraulic clamping force doubling design, easy to operate, suitable for light and heavy cutting

3. The body and the fixed jaw are integrally formed, and the workpiece wont go upwards when clamped.

4. The sliding surface of vise has been hardened to HRC45 or higher, ensuring long-term wear resistance.

5. Four clamping ways meet with different requirments.

6. Material: Ductile cast iron.

| Model | A | B | C | D | E | F | G | H | I | J | J1 | J2 | J3 | K | M | X | GW,kg | NW,kg |

| DYV4-130 | 464 | 340 | 124 | 102 | 130 | 133 | 65 | 15 | 110 | 0-130 | 65-210 | 110-240 | 175-305 | 48 | 18 | 65 | 28 | 37 |

| DYV5-180 | 539 | 415 | 124 | 130 | 147 | 163 | 75 | 15 | 138 | 0-180 | 75-270 | 125-305 | 213-393 | 55 | 18 | 45 | 35 | 44 |

| DYV6-240 | 604 | 480 | 124 | 160 | 160 | 163 | 85 | 15 | 118 | 0-240 | 85-320 | 138-358 | 223-443 | 58 | 18 | 99 | 44 | 53 |

| DYV6-300 | 664 | 540 | 124 | 160 | 160 | 163 | 85 | 15 | 118 | 0-300 | 85-400 | 138-438 | 223-523 | 58 | 18 | 99 | 49 | 58 |

| DYV8-340 | 734 | 610 | 124 | 200 | 187 | 190 | 100 | 18 | 130 | 0-340 | 100-458 | 230-570 | 230-570 | 70 | 18 | 70 | 75 | 84 |

| Model | A | B | C | D | E | F | G | H | I | J | J1 | J2 | J3 | K | M | X | GW,kg | NW,kg |

| DYV4-130 | 464 | 340 | 124 | 102 | 130 | 133 | 65 | 15 | 110 | 0-130 | 65-210 | 110-240 | 175-305 | 48 | 18 | 65 | 28 | 37 |

| DYV5-180 | 539 | 415 | 124 | 130 | 147 | 163 | 75 | 15 | 138 | 0-180 | 75-270 | 125-305 | 213-393 | 55 | 18 | 45 | 35 | 44 |

| DYV6-240 | 604 | 480 | 124 | 160 | 160 | 163 | 85 | 15 | 118 | 0-240 | 85-320 | 138-358 | 223-443 | 58 | 18 | 99 | 44 | 53 |

| DYV6-300 | 664 | 540 | 124 | 160 | 160 | 163 | 85 | 15 | 118 | 0-300 | 85-400 | 138-438 | 223-523 | 58 | 18 | 99 | 49 | 58 |

| DYV8-340 | 734 | 610 | 124 | 200 | 187 | 190 | 100 | 18 | 130 | 0-340 | 100-458 | 230-570 | 230-570 | 70 | 18 | 70 | 75 | 84 |

Q: Are you a factory or tading company?

A: We are an integration of factory and trade.

Q: What payment service do you offer?

A: We offer T/T, Paypal, Western Union, Cash.

Q: What is your term of delivery?

A: We accept EXW, FOB, CFR, etc. You can choose the one which is the most convenient or cost-effective for you.

Q: How long is your delivery time?

A: Generally it is 7-10 days if goods are in stock, otherwise it is usually 20-30 days, it is according to your order quantity.

Q: Are you a factory or tading company?

A: We are an integration of factory and trade.

Q: What payment service do you offer?

A: We offer T/T, Paypal, Western Union, Cash.

Q: What is your term of delivery?

A: We accept EXW, FOB, CFR, etc. You can choose the one which is the most convenient or cost-effective for you.

Q: How long is your delivery time?

A: Generally it is 7-10 days if goods are in stock, otherwise it is usually 20-30 days, it is according to your order quantity.

content is empty!