- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

Views: 0 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

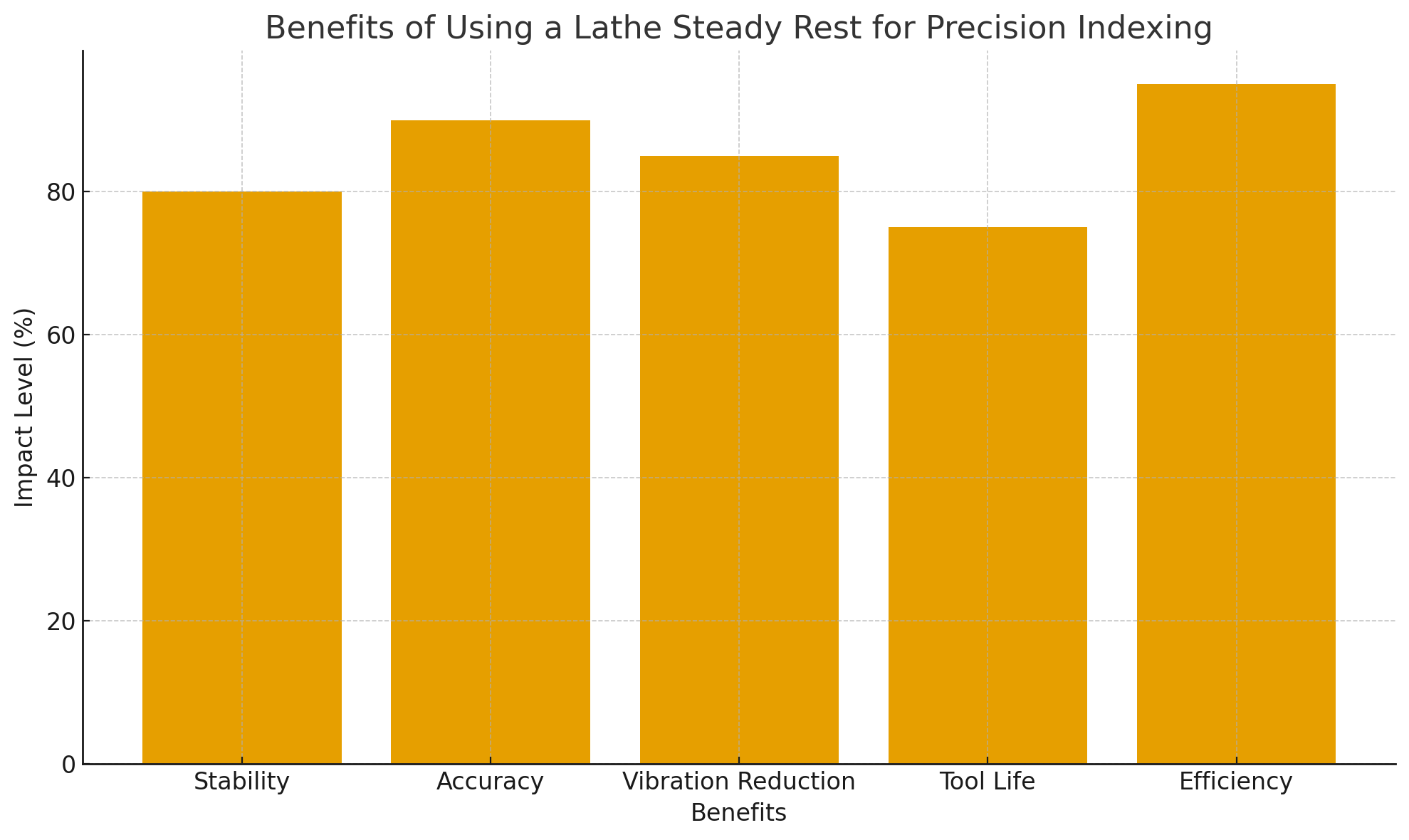

In machining, precision indexing is key to creating high-quality parts. Achieving tight tolerances, especially with long or slender workpieces, can be challenging. A lathe steady rest provides the necessary support and reduces vibrations, improving both accuracy and stability. In this article, we will explore how a lathe steady rest enhances precision indexing.

A lathe steady rest is a fixture that stabilizes the workpiece while it is being turned on a lathe. It provides support to long or slender parts, preventing deflection, vibration, and misalignment during machining. Steady rests are mounted on the lathe bed and are designed to provide support at multiple points along the length of the workpiece. This allows for more consistent and precise operations, especially when the workpiece extends beyond the chuck or collet.

Precision indexing refers to the process of accurately rotating the workpiece to specific positions for machining. It is crucial in operations like turning, drilling, and threading. When performing precision indexing, maintaining the alignment and stability of the workpiece is vital to ensure that all cuts are accurate and the final part meets required specifications. Without proper support, especially for long or flexible workpieces, achieving consistent and precise indexing becomes a challenge.

A lathe steady rest enhances precision indexing by keeping the workpiece firmly centered and reducing deflection. During turning operations, especially on long workpieces, cutting forces can cause vibrations or slight shifts in the workpiece, leading to inaccuracies in indexing. The steady rest prevents this by offering consistent support, allowing for smooth rotation and maintaining the alignment of the workpiece with the lathe axis. This minimizes the risk of vibration, which in turn helps achieve better surface finishes and tighter tolerances.

Long workpieces, such as shafts, are especially susceptible to deflection and vibration when machining. A lathe steady rest provides the necessary support to keep these workpieces stable, preventing unwanted movement that can lead to poor machining results. This is crucial when turning long shafts or tubes that might otherwise bend or wobble under the pressure of the cutting tool. By supporting the workpiece along its length, the steady rest ensures that it remains rigid and stable during machining, leading to more accurate and consistent results.

Vibrations during machining can lead to errors, especially in precision indexing. When vibrations are minimized, the lathe can cut with greater accuracy, and the workpiece can be indexed precisely. A lathe steady rest significantly reduces these vibrations by providing steady support. With less vibration, the tool experiences less wear, and the workpiece receives a cleaner, more precise finish. This reduction in vibration helps achieve tighter tolerances and higher-quality parts.

The stability provided by a steady rest not only improves accuracy but also extends the life of cutting tools. When vibrations are reduced, tools wear less quickly and perform better. This also leads to fewer tool changes and less downtime. As a result, machining operations become more efficient, allowing manufacturers to produce parts faster and at a lower cost. By minimizing tool wear and enhancing stability, a lathe steady rest helps optimize the entire machining process.

Benefit | Description |

Improved Precision | Stabilizes the workpiece, preventing misalignment and ensuring accurate indexing. |

Reduced Vibration | Minimizes vibrations during machining, improving surface finishes and tool life. |

Enhanced Workpiece Support | Provides additional support for long or slender workpieces, preventing deflection. |

Increased Tool Life | Reduces wear on cutting tools by stabilizing the workpiece and reducing vibrations. |

Increased Efficiency | Helps maintain tight tolerances, ensuring consistent results and faster machining. |

There are two main types of lathe steady rests: fixed steady rests and traveling steady rests.

● Fixed steady rests remain stationary on the lathe bed and provide support at specific points along the workpiece. These are ideal for operations where the workpiece doesn't need to move during machining. Fixed steady rests are commonly used in operations like turning and facing.

● Traveling steady rests, on the other hand, move along with the carriage as the lathe tool advances. This type of steady rest provides continuous support at the cutting zone, making it ideal for turning long or slender parts without tapering or deflection.

Both types enhance precision indexing, but the choice between fixed and traveling rests depends on the specific machining operation and the requirements of the workpiece.

Some applications require customized lathe steady rests to accommodate specific workpieces or machining needs. For example, when working with very large or unusually shaped parts, a specialized steady rest can provide the necessary support. Custom steady rests can be tailored to fit specific workpiece dimensions, allowing for more versatile and precise machining. Industries such as aerospace, automotive, and medical device manufacturing often require these specialized solutions for high-precision operations.

Type | Description | Best Suited For |

Fixed Steady Rest | Stationary support mounted on the bed of the lathe. | Long workpieces requiring support during turning, facing, and boring. |

Traveling Steady Rest | Moves with the cutting tool to provide support during machining. | Operations that require continuous support near the cutting zone. |

Roller Steady Rest | Features precision rollers to reduce friction and wear. | High-speed operations or machining delicate materials. |

Specialized Steady Rests | Custom-made rests designed for specific machining needs. | Custom applications, such as aerospace, automotive, or medical parts. |

To get the most out of a lathe steady rest, it is crucial to properly set up and align the fixture. Misalignment can lead to uneven support, causing inaccuracies during indexing. When installing the steady rest, ensure that it is positioned correctly and aligned with the lathe axis to maintain the workpiece’s stability. Additionally, it is important to check the workpiece for any irregularities before using the steady rest to ensure that it remains centered during machining.

Regular maintenance is essential to ensure that a lathe steady rest functions optimally over time. This includes cleaning the steady rest and lubricating the moving parts to reduce wear. Regular inspections of the steady rest can help identify potential issues before they affect performance. Proper maintenance extends the lifespan of the steady rest and ensures that it continues to provide the necessary support for precision indexing.

Step | Action |

1. Alignment | Ensure the steady rest is properly aligned with the lathe's centerline. |

2. Adjustment of Jaws | Adjust the jaws to fit the workpiece securely without applying excessive pressure. |

3. Workpiece Preparation | Machine a true running surface for the steady rest to contact. |

4. Lubrication | Apply lubricant to reduce friction between the steady rest and workpiece. |

5. Checking Stability | Ensure the steady rest holds the workpiece firmly with minimal movement. |

One common issue when using a steady rest is misalignment, which can lead to inaccurate indexing and machining errors. To avoid this, ensure that the steady rest is properly aligned with the workpiece and the lathe axis. If alignment issues persist, consider using adjustable steady rests that allow for finer control over positioning. Regularly calibrating the steady rest also helps maintain accurate alignment.

While lathe steady rests are highly effective for many machining tasks, they may not be suitable for all operations. In some cases, complex or highly irregular workpieces may require additional support or different types of fixtures. For operations that demand even more precision, consider using custom-designed steady rests or combining them with other workholding solutions to achieve the desired results.

Using a lathe steady rest is crucial for precision indexing in lathe operations. It provides stability and reduces vibration, improving machining accuracy, tool life, and efficiency. For industries needing tight tolerances and high-quality finishes, investing in a top-notch steady rest is key. Yantai Formore Machinery Co., Ltd. offers custom-designed lathe steady rests that enhance precision and optimize performance, helping manufacturers achieve superior results with every turn.

A: A lathe steady rest is a workholding device that stabilizes the workpiece during machining. It prevents deflection, vibration, and misalignment, ensuring accurate cuts.

A: The lathe steady rest maintains the centerline of the workpiece, preventing misalignment and deflection during precision indexing, which leads to improved accuracy.

A: For long or slender workpieces, a steady rest provides additional support, preventing deflection and vibrations, which are crucial for maintaining precision.

A: Yes, there are fixed and traveling lathe steady rests. Fixed rests provide stationary support, while traveling rests move with the carriage, offering continuous support during machining.

A: By reducing vibrations and stabilizing the workpiece, a lathe steady rest minimizes wear on cutting tools, extending their lifespan and improving overall efficiency.